Electric Press Brake

Electric servo press brakes are highly versatile and suitable for a variety of applications,including precision sheet metal bending.small household appliances,and computer and equipment enclosures.They are designed for bending metal materials and are well-suited for precision sheet metal components and mechanical manufacturing parts.

The most popular sports event in the world

Energy conivation

One month's electricityconsumption is 1/4 of that of a regular hydraulicbending machine.

Environment protection

No hydraulic oil is used, so there is no oilleakage, which makes the workshop cleaner.cleaner,and more environmentally friendly.

High efficiency

By using servo motors and screw control, the efficiency ofthe entire cycle is doubled compared to hydraulic bending machines.

Accurate

Byrelying on servo motors and screw rotation, the slider can move up and down, and the positioning accuracy can still be maintained during long-term operation.

Product features

Stable and Durable

Alladopt imported servo motorsto ensurethe accuracyand stabilityofthe machinery, and itis also durable.

High precision and long service life

The screw guide rails are all imported C5 grade products with high precision.eycellent performance. andlona service ife The minimum movement seftina unit forthe D-axis is 0.005mm.

Especially power-saving

The difference in electricityconsumption between the fullyelectric servo bending machineand the electro-hydraulic servo bending machine is similarto the difference between variable frequency air conditioningand ordinary air conditioning.The fully electric servo bending machine automatically outputs appropriate power andenergy according to the working conditions, and consumes less than 0.5kW ofelectricitywhen idle, so it is particularlyenergy-saving.

Green and environmentally friendly

No needto use orreplace hydraulic oil,endina the pollution of waste hydraulic oi totheenvironment.

Component features

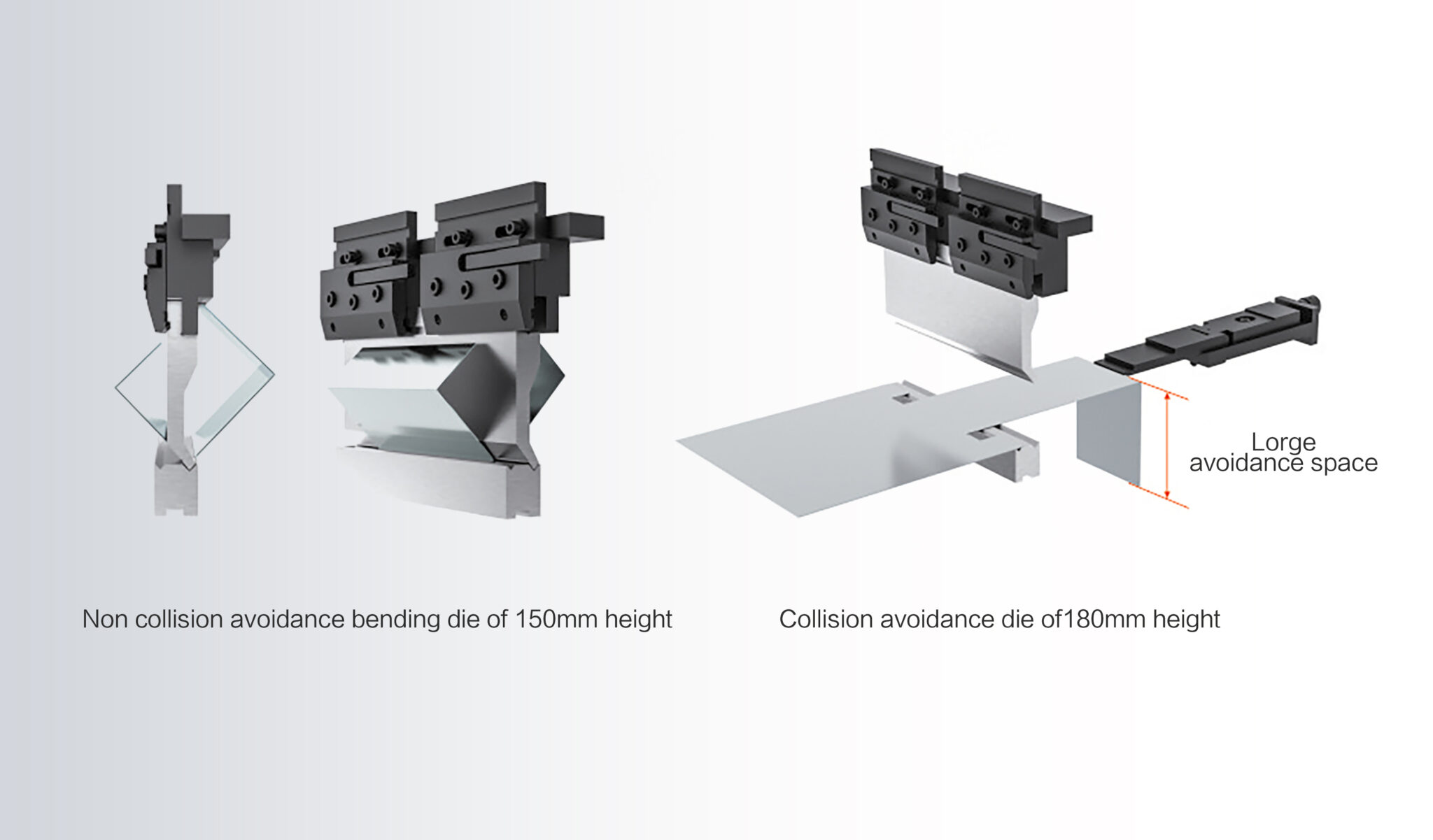

MultifunctionalAvoiding Space

Each mode lof our bending machine has suficient space for sheet metal to avoid interference. lt can produce all kinds of complex sheet metal parts with out worries for users.The slider stroke space ofthe bending machine is large, and the upper die with a height of 180mm-210 can be clamped according to different models.

Back Gauge Structure

The crossbeam is processed with high-qualitycarbon steel,and the over all structural design is simple, compact, and stable resulting in fast speed and high accuracy.

The standard configuration for the rear material blocking of this machine is X and Y axes, with 2 adjustable blocking fingers

Bending Machine System

Switch between Chinese and English interfaces.

Programming is simple and easyto operate, withsmooth and seamlessinterface operations fromprogram, mold, synthesis, programming tobending.

2D graphic programming, display, and simulationfunctions, as wellas high-speed accelerationand deceleration algorithm functions.

Main Structure And Working Principle

This machine tool mainly consists ofa frame, a slider, a rear material blocking structure, a control system, and a mold

Rack:

Adootina on o stee weded structure with sufficient strenath and rididity.and simulatina realload conditionsthrough finite element analysisto achieve the required load conditions. After welding, annealing treatment is usedtoeliminate residual stresses in the frame welding.

Sliding block:

This machinetooladopts an eccentri axis guided sliding block structure, which has a simple overallstructure andis convenient for debugging and maintenance.

Control System:

Adopting NCmax CNC bending system,this system is independentlydeveloped,with flexible and simpleoperation, which can be operated without the need for skilled operators,The proaram is simple and fast. and orocessinocan be carriedout withoutthe needto input mold data in advance.Data modification and execution are on the samedrawina surface. savinatime and simplifyina operations,Each axis uses relative positionto record the origin, withoutthe problem ofdisappearance and resetting ofthe origin.

Mold:

This component consists ofan upper mold component anda lower mold component.The upper mold is installedonthe slider ond fixed bva clamp plote.Thelower mold can be in various forms such as sinalev. doublev. and multinlevThe mold can be segmented or customized accordingto userrequirements.

Working principle:

Directly driven bya servo motor, the screw rod achieves high-speed rise and fall, stable repetitiveaccuracy, and efficient production.